Made in China, high-end PCB electroplating electrolytic diaphragm to achieve mass production

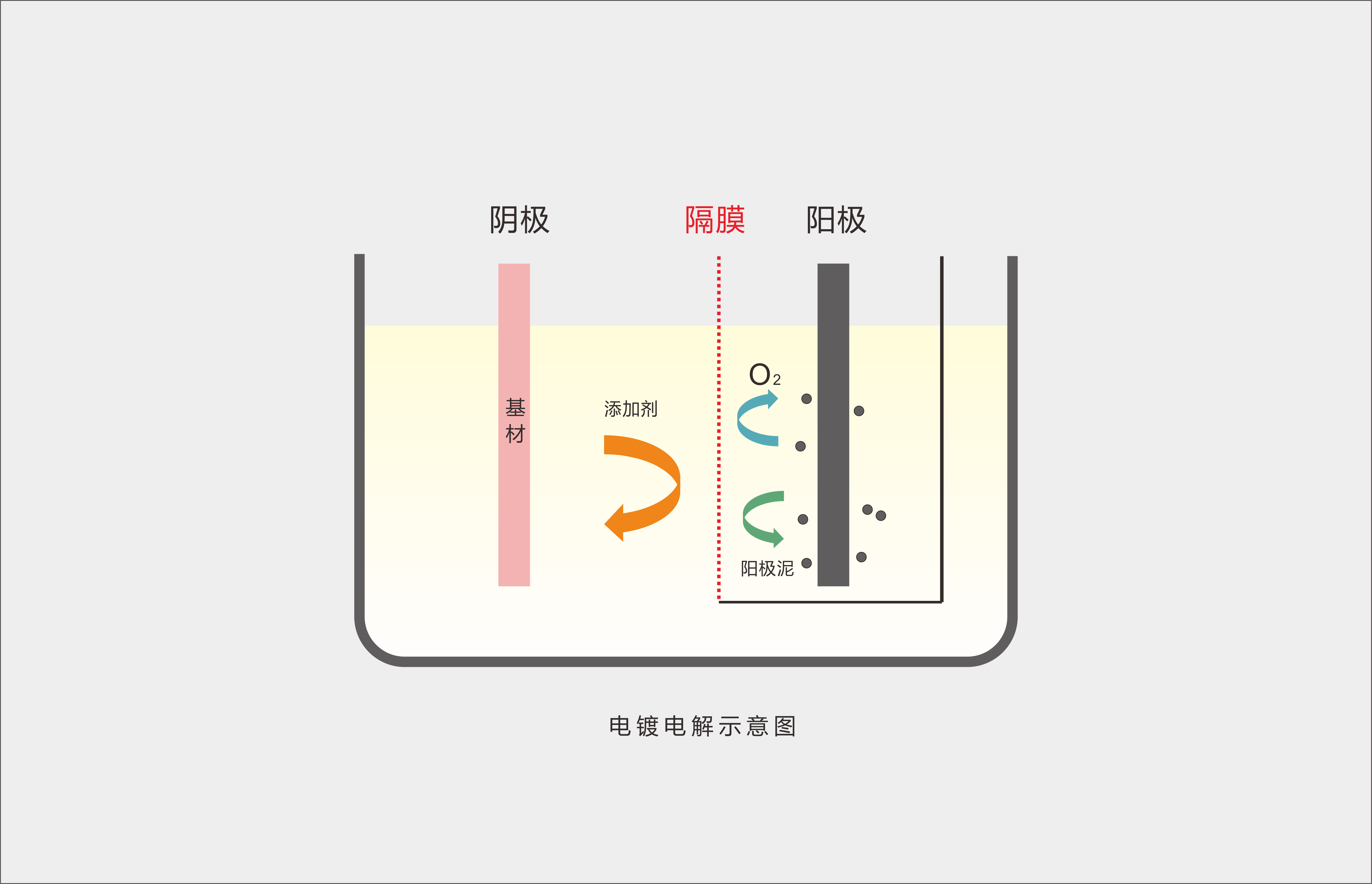

In the field of copper plating, especially in the field of high-end PCB plating, electrolytic diaphragm technology has long been monopolized by the Japanese GS Yuasa company. The electroplating electrolytic diaphragm is a kind of neutral diaphragm material with a microporous structure, which can allow electrons and other small molecules (such as water) to pass through the electrolytic system, while blocking larger molecular size additives, thus forming a "vacuum zone" of additives at the positive extreme, reducing the anode loss of additives, and significantly reducing the cost of electroplating.

At present, the research and development team of Kervoch technology has successfully developed a PCB electroplating electrolytic diaphragm with the same performance, and successfully realized the replacement of imported products. This is another high-end diaphragm product launched by the research and development team of Kervoche for the market after the alkaline hydrogen production composite diaphragm product. This domestic electrolytic diaphragm has reached the international advanced level in performance, has the capacity of mass production, and has begun to ship to the market.

The PCB electroplating electrolytic diaphragm has low resistance, strong chemical resistance and other characteristics, the film thickness is 0.22mm, can withstand the long-term corrosion of chemical substances in the electroplating solution, and maintain lasting stability, can delay the contact between additives and electrolytic cell anode, especially suitable for insoluble anode, reduce the sharp loss of electrolytic additives during the electrolysis process of insoluble anode. Improve plating quality and production efficiency, and help enterprises to further save costs.

At the same time, the diaphragm can also be processed into strip, bag, frame welding and other shapes according to customer needs, and can be stored in a dry state.

With the successful development and batch shipment of PCB electroplating electrolytic diaphragm, it will greatly reduce the dependence of domestic electroplating manufacturers on imported products, improve the independent control ability of the domestic PCB electroplating industry, provide more cost-effective options for domestic electroplating enterprises, enhance the overall competitiveness, and lay a solid foundation for the sustainable development of the electroplating industry.

In the future, the R&D team will continue to deeply cultivate electrolytic diaphragm technology, increase R&D investment, and commit to developing more new high-end diaphragm materials to meet the changing market demand and make greater contributions to the progress and development of human society.